Technicals

Now the fun part for all you technically adept buyers…

One of our biggest points of pride is that when engineers come to see our product, they buy our product. We ask our clients to pay us a visit (or ask for a site visit), then go and compare the sheer quality difference between a Mr.Pergola system compared to, literally, any other pergola on the market, Bar None! Mr.Pergola comes on top.

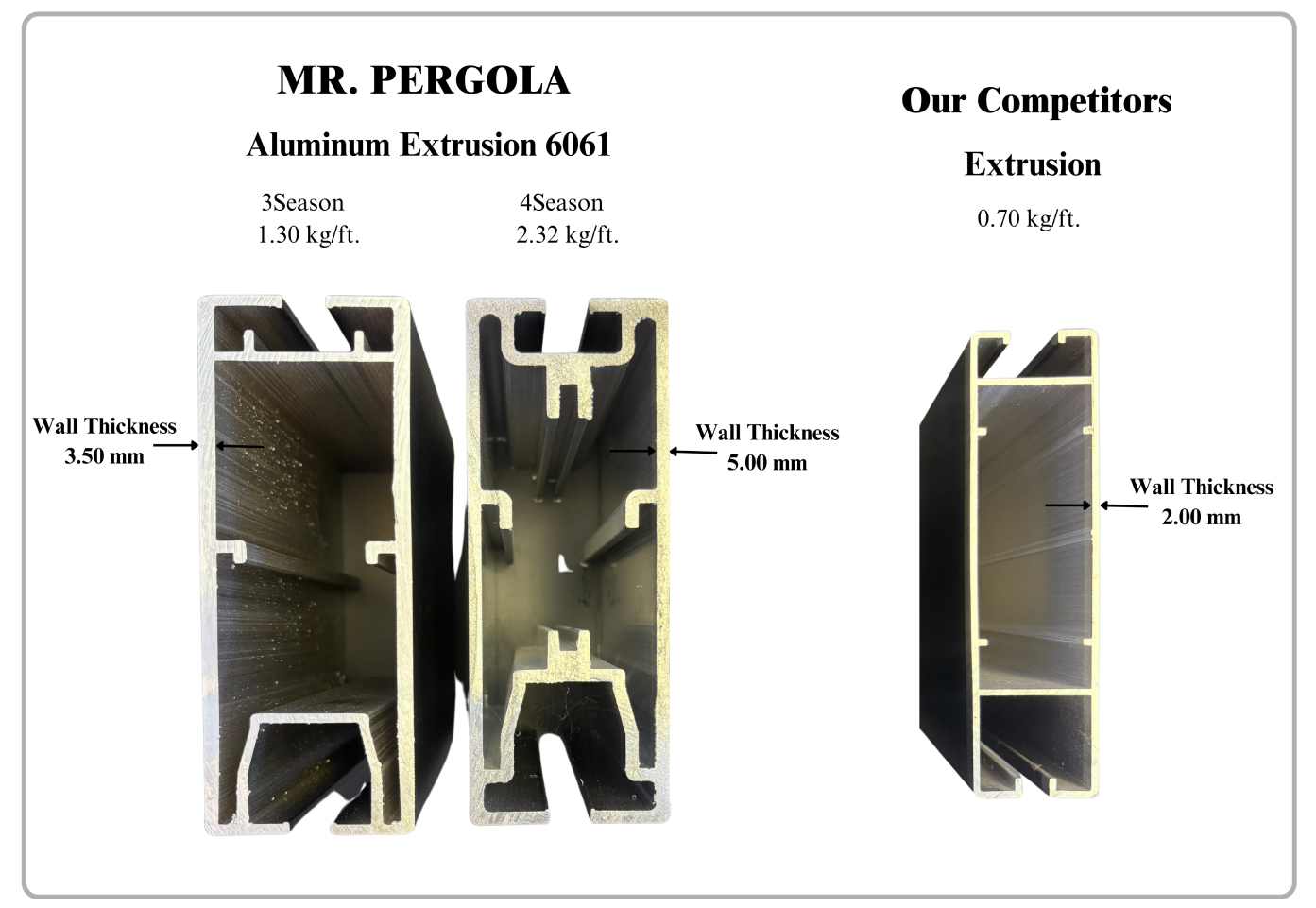

We studied our competitors, even went as far as buying competing products to see what works and doesn’t for the North American market. We came up with our own solution…. 2 different systems for 2 different use cases. 3 Season and 4 Season….

Well over a thousand hours of engineering went into our design and development, add another small fortune for testing and validation by 2 engineers who signed off on the design.

3-SEASON PERMANENT PERGOLA

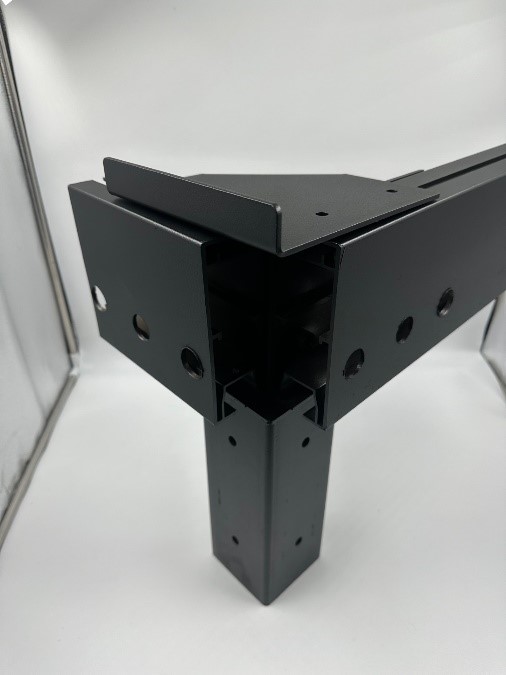

First, the most solid permanent 3-Season Pergola. Where you can support some snow (3-4inches), but is built to be left open in winter. As the pics below show, we use high grade steel and aluminum. One way to see the strength of any pergola is by looking at the corner brackets… since corners give strength. Our competitors use flimsy bent sheet metal with #12 screws to make a corner (pic below)… we use 10g steel and 6 Grade-8, half-inch bolts, (yes half inch) for each corner. See pics below. Our unique corner bracket also has a 4”x 4” HSS underneath going down 12” to help against the wind. The electroplated black zinc bolts of the posts (3/8” x 5”) keep the entire frame in place. We’ve installed our pergolas by the Saint Laurence River, Oka Lake, plenty rooftop patios, by highways and never, ever, have we had any problems. In the rare cases where need be, we created an additional bracketing system to shore it up further, where we can stand up to constant Cat3 Hurricane winds (125mph-208km/hr). There is simply no other pergola that can stand up to Mother Nature like Mr.Pergola can. Period.

4-SEASON PERMANENT PERGOLA

Now for the 4-Season Pergola… It’s nothing short of a Beast! The only pergola in the world that can handle 3 feet of wet snow, which means you can use it carefree all winter long. We see other companies talking about Snow Load in weight (ex: 6000lbs-11000lbs), but this is misleading. SNOW IS HEAVY! A few thousand pounds amounts to a few inches of snow…none come close to 3 feet (22,000lbs on a 16×16)! … for the record, our snow load capacity is 80 pounds per square foot. That’s double anyone else’s claims. The difference between our claims and our competitors is that we have our pergolas tested by specialized engineering firms and two engineers signed off on it. We don’t simply put some weight on the pergola and make a claim, we invested, heavily, so that we can guarantee our claims!

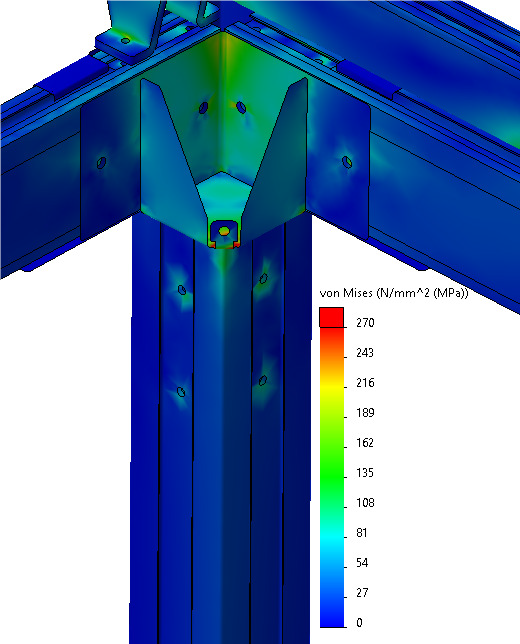

This pergola is of course more expensive given the quantity of materials we use. The corner brackets are quarter inch (1/4”) thick steel, properly covered to last, frankly, as long as you want it. There are almost no points of failure. We studied what others have done, found the weak points and solidified our system, essentially learning from their mistakes and weaknesses. There is a reason we can go up to 20ft wide and 20ft deep with only 4 posts…and why our louvres (blades) can surpass the frame by 4ft, without dropping/bending.

The 4-Season pergola option is perfect for those who want to use their patio in winter because they have an outdoor kitchen, love to BBQ, want to store their furniture without having to cover it or simply enjoy taking a break outside in winter with a firepit and either a hot chocolate or a cigar…

100% Waterproof

CUSTOMIZATION

Our classic pergola can be customized like no other. We can do anything from height extension, L-Shaped, extended louvres or extended sub-frame for more coverage when you have a smaller footprint to work with. The attached pergola is an option if your home’s exterior can support it. We have special mounting brackets for this purpose.

Classic Pergola | Modern Pergola | |

|---|---|---|

Adjustable Louvres | ✓ | ✓ |

Louvres Lock at any angle | ✓ | ✓ |

Manual Mechanism |  |  |

Electric Mechanism Option | ||

Built in rails for curtains (left to right) | ✓ | ✓ |

Electric Curtains (vertical movement) | ✓ | ✓ |

Heavy Gage Aluminum | ✓ | ✓ |

Rain Run Off | Any direction of louvres | Integrated Gutters |

Span (distance between posts), both deep and wide | up to 20ft | up to 20ft |

Grade 8 Bolts (McMaster: 90128A714) | ✓ | ✓ |

4 Season Capable | ✓ |

3-Season | Louvres open in winter | 4-Season | Louvres closed in winter | |

|---|---|---|

6063 Aluminum Beams | ✓ | ✓ |

Additional Support Beams | If necessary or desired for lights/heaters | ✓ |

Extrusion Profiles | 6″ | 6″ |

Aluminum Post 6061 | ✓ | ✓ |

Support/”Brackets”-Thickness | 1/8″ | 1/4″ |

Compatible Accessories | ✓ | ✓ |

Internal Reinforcements | 18″ and over | ✓ |

Dynamic charge (constant wind-closed louvres) | 208KM/HR | 208KM/HR |

Static charge (Snow) | First snow fall only (2-4) | 36″/88lbs |

Our wind rating tests are not done by renting a big fan as some other companies do…and then proudly display it on video as if it’s an actual test…NO!

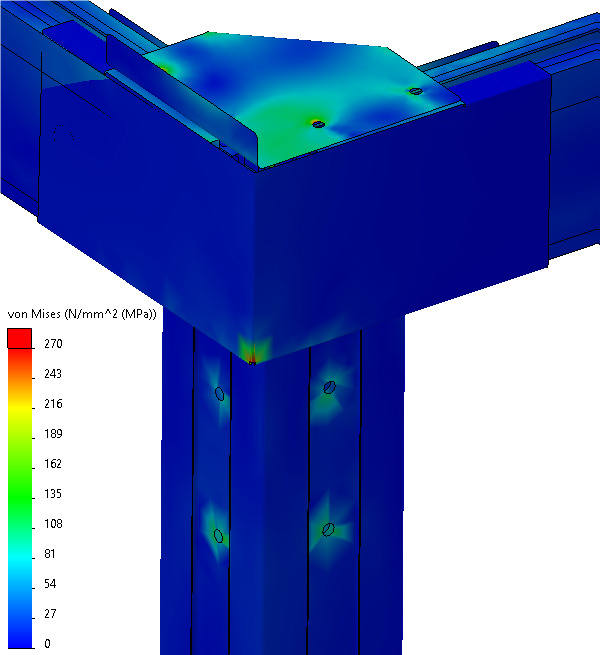

Our tests are done by a professional firm out of Quebec City specializing in structural engineering and finite element analyses (FEA)… Concept ParaDesign. Our Account Manager, engineer Mr. Olivier Morin who’s been working with Mr.Pergola designers from inception. He knows the ins-and-outs of what we do. He’s always ready to answer questions on the go, or put together the model for the next test… He knows Mr.Pergola better than Mama Pergola!

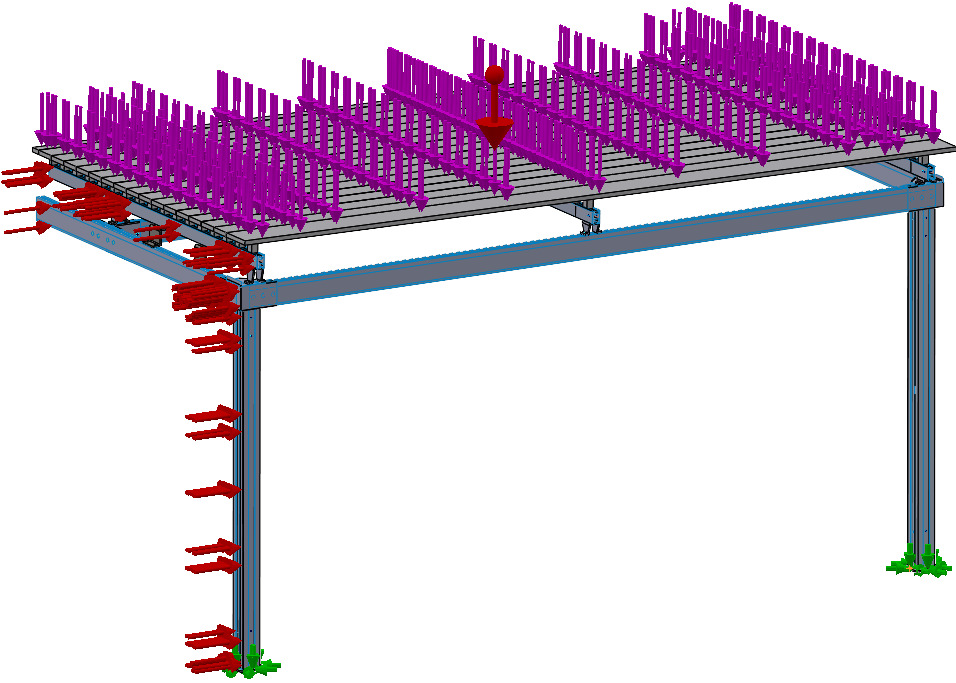

DYNAMIC CHARGE : WIND

Here is what a professional test profile looks like, showing the forces being excreted on the pergola. This image is from one of the pages of the report produced by Concept Para Design, one page of many.

(448 N/m2 wind perpendicular from one side / 12.2625 m/s2 of gravity)

STATIC CHARGE: SNOW LOAD

Snow load calculations are done using sophisticated software and entails hours upon hours of calculations. Further, following the Canadian Building Code of 2015, which is a recognized and accepted global standard, the tests and engineering work doesn’t end until we achieve a minimum of 24” of wet snow (36” of powder snow), plus a classified buffer.

We took the necessary time (and expense) to work with designers and mainly engineers to ensure we pass any test. We are currently working to pass the necessary wind rating of a Cat 3 Hurricane.

Inside Out Test

Inside Out/Mr.Pergola

Outside In-1/Mr.Pergola

Mr.Pergola Corner Test

Mr.Pergola Corner Aluminum Cover

Competition Corner

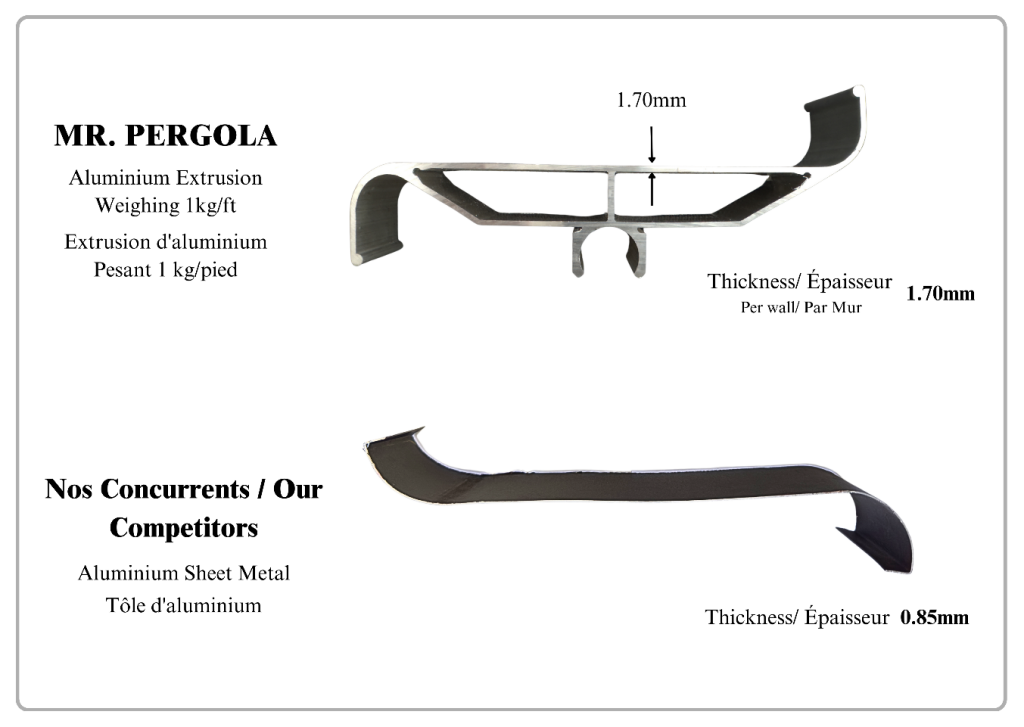

Now compare our corner bracket to what you get from our competitors (actual image from competitor pergola), a folded piece of sheet metal with a few #12 screws. Just by looking at this pic, you know the top (louvres) are not substantial. Their louvres are also made of SHEET METAL, NOT EXTRUSIONS.

See comparison pic below. Whereas our louvres can handle 195kg of snow each (16ft-4-Season Pergola with adequate frame reinforcements), Sheet Metal can barely handle its own weight.

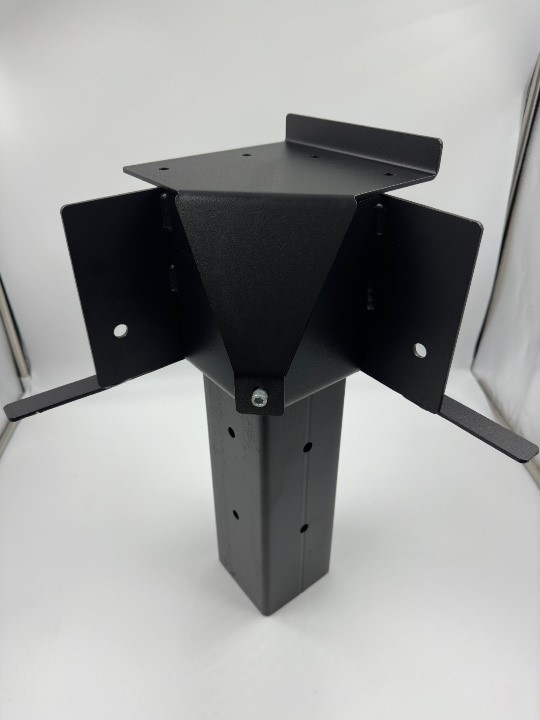

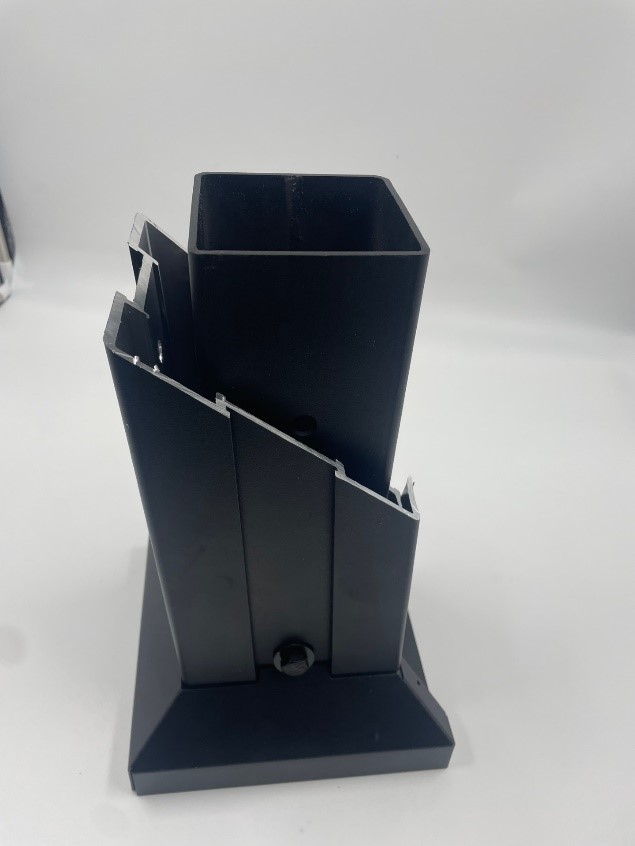

The base foot of our system is extremely solid. You can hold your pergola on 4 pins because of the thickness of our post and the base system. The extra corners on the post give it immense strength, simple more corners = more strength. (actual parts, not photoshopped)

3 Season Base Foot System

4 Season Base Foot System

| STANDARD SIZES (4-Post or Wall Mount) | ||||||

|---|---|---|---|---|---|---|

LOUVRES / DEPTH |

WIDE | |||||

| 12 | 14 | 16 | 18 | 20 | ||

| 10 | 12 x 10 | 14 x 10 | 16 x 10 | 18 x 10 | 20 x 10 | |

| 12 | 12 x 12 | 14 x 12 | 16 x 12 | 18 x 12 | 20 x 12 | |

| 14 | x | 14 x 14 | 16 x 14 | 18 x 14 | 20 x 14 | |

| 16 | x | x | 16 x 16 | 18 x 16 | 20 x 16 | |

| 18 | x | x | x | 18 x 18 | 20 x 18 | |

| 20 | x | x | x | x | 20 x 20 | |

Free Customization (cut to fit)